- 技术说明

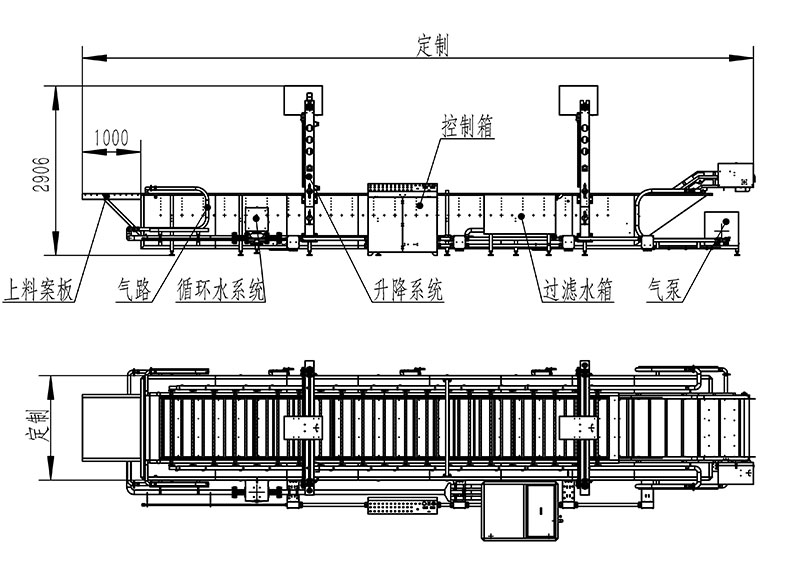

- 尺寸参数

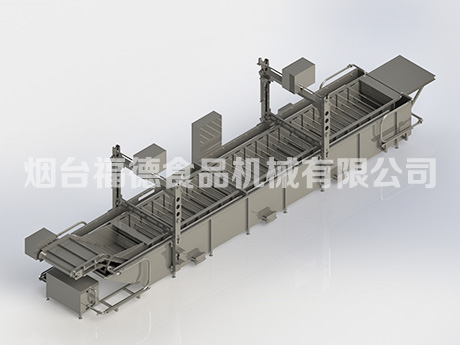

1、本产品主要用于水产品块冻品解冻,从冷藏库中出来的待加工的产品通过预解冻,然后后再通过解冻机解冻,从而达到后续工序要求;

2、解冻机工作原理:采用环境中的热量,通过涡旋气泵将环境中的热量送入解冻槽内形成较大的气泡,气泡带动水冲击需要解冻物品,逐层将冻品解冻;

3、解冻后的产品随输送带立刻输送出去,未解冻的产品继续解冻,从而到达需要解冻的产品解冻程度一致,确保产品品质;

4、在解冻过程中为低温解冻,避免了产品变色,提高产品品质;

5、本产品设计理念先进,输送部件可升降,便于卫生清理,完全满足食品卫生要求;

6、超大排污口,排污更快捷、方便,大大节约清理时间;

7、电气元器件采用进口施耐德品牌,安全可靠;

8、本解冻机解决了人工解冻耗时、浪费水、解冻不均匀的情况。

9、如需解冻效率更高,用户可自行配置蒸汽源,我公司产品根据用户现有资源进行定制设计,力求将用户现有资源发挥到最好程度;

1.The product is mainly used to defrost frozen aquatic products. The products out of refrigerator to be processed will be firstly pre-defrosted and then defrosted by thawing machine in order to meet following processing requirements;

2.Working principle of thawing machine: Ambient heat is sent to thaw slot via vortex pump to form larger bubbles, which drive water to wash products to be defrosted so as to defrost them layer by layer;

3.Defrosted products are immediately sent out via conveyor and frozen products are continuously defrosted in order to meet defrosted product requirements and ensure product quality;

4.Defrosting process is carried out under low temperature in order to avoid discoloration of products and improve product quality;

5.The product is designed with advanced concept and transmission part can be raised or lowered for convenient cleaning in order to meet food hygiene requirements;

6.Large drain outlet is used for quick and convenient drainage and a large amount of cleaning time is saved;

7.Schneider electrical components are used to provide sufficient safety;

8.The thawing machine solves time consuming, water wasting and uneven thawing problems of manual defrosting.

9.If higher defrosting efficiency is required, users can use steam source. Our products can be customized according to existing resources available to users in order to maximize their applications;